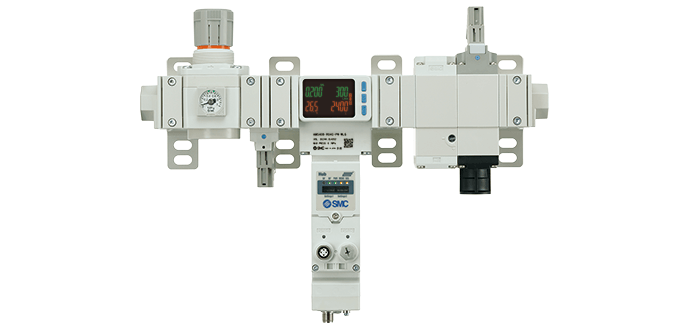

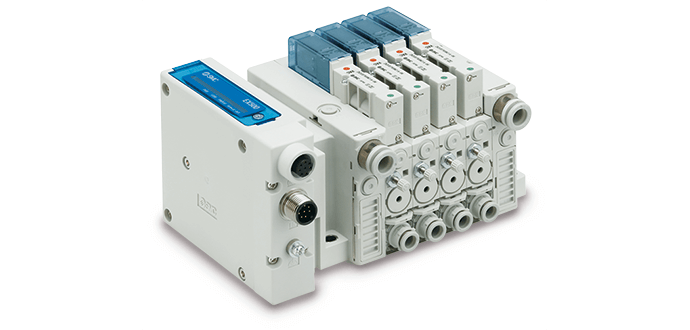

Air Saving Modular Air Prep

Featured Product

Air Saving Modular Air Prep

The Air Management System is available in two basic configurations that vary by the standby regulator used. The A type utilizes the electro-pneumatic regulator while the B type uses the manual type standby regulator. The hubs have an extra IO link port for connection to additional devices that can communicate through the system.

Product Innovations

Energy Saving Products

In our 24/7 economy and as Governments, industries and consumers battle with our thirst for ever increasing supplies of energy, SMC has always been fully committed to assist customers in reducing their bills and of course, in making its modest contribution to global sustainability. We now want to share our 5 cornerstones of energy efficiency with you that will help you to embrace good energy policies for your business in a very intuitive and simple way.

Featured Video

Condition-Based Maintenance Solutions

With SMC’s Condition-Based Maintenance approach we are able to guide your company to the next levels of corrective actions by helping to eliminate unexpected downtime and in-service failures, ensuring ongoing performance and availability.